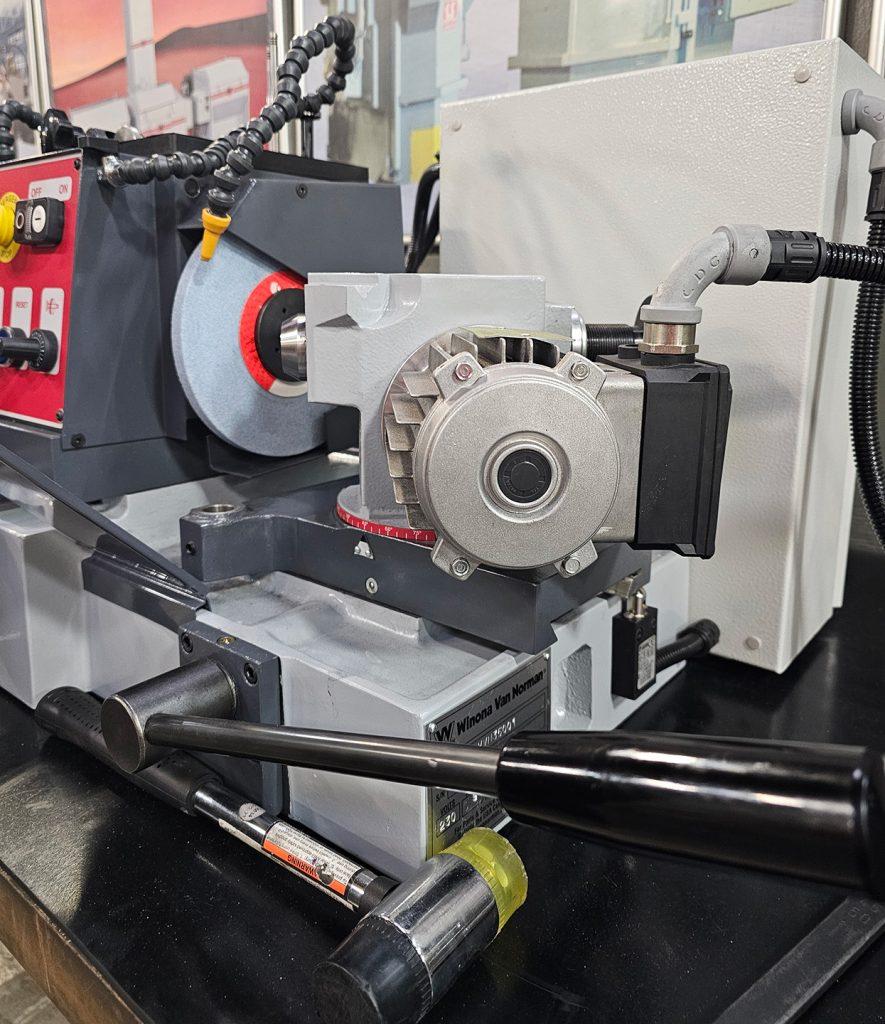

Valve Refacing Grinder VRX

The VRX Valve Refacing/Grinder is a precision machine designed to reface valves and chamfer or recondition valve stem butts with high accuracy. Featuring a direct-drive motor for the grinding wheels, it eliminates belt slippage and ensures consistent grinding power. The machine is easy to operate, with a rigid cast base for stability and dovetail guide carriages that allow precise clearance adjustments. Valve heads are clamped in a collet system that guarantees tight concentricity and accurate centering, while the valve head stock adjusts from 15° to 60°, enabling versatile operation.

Additional features include hand-crank and handle-fed feeds for the grinding wheel and chuck, positive stops for repeatable valve stem grinding, and V-ways for consistent chamfering. The VRX uses water-based coolant supplied via a gear pump and settling tank for a superior finish and easy cleanup. Multiple high-quality grinding wheels accommodate different valve materials, and two sizes of ball chucks allow ultra-precise operations with a tolerance of 0.0002 TIR, making it ideal for high-precision, high-efficiency valve refacing tasks.

Request A Quote

Product Information

Operations

Specifications

Coolant system, collet from .236‐.354″, collet from .354 ‐ 472″, collet from .472 ‐ .629″, support for diamond holder, grinding wheel 6″ x 5″ (.5″ arbor), valve stop, positive stop, grinding rocker arm fixture, diamond and rest, 1 qt of coolant, service tools, operating manual.

Features

Standard Tooling

Features and Options

Min. – Max. Diameter Valve Stem:

Max. Diameter of Valve:

Grinding Angle:

Grinding Wheel Diameter:

Grinding Wheel Speed (Variable):

Spindle Speed (Variable):

Grinding Wheel Motor Power:

Spindle Motor Power:

Electrical:

0.157″ – 0.689″

3.543″

15° – 60°

6″

0 – 2,800 RPM

0 – 55 RPM

0.25″

0.1 HP

115V/50HZ or 220V/50HZ