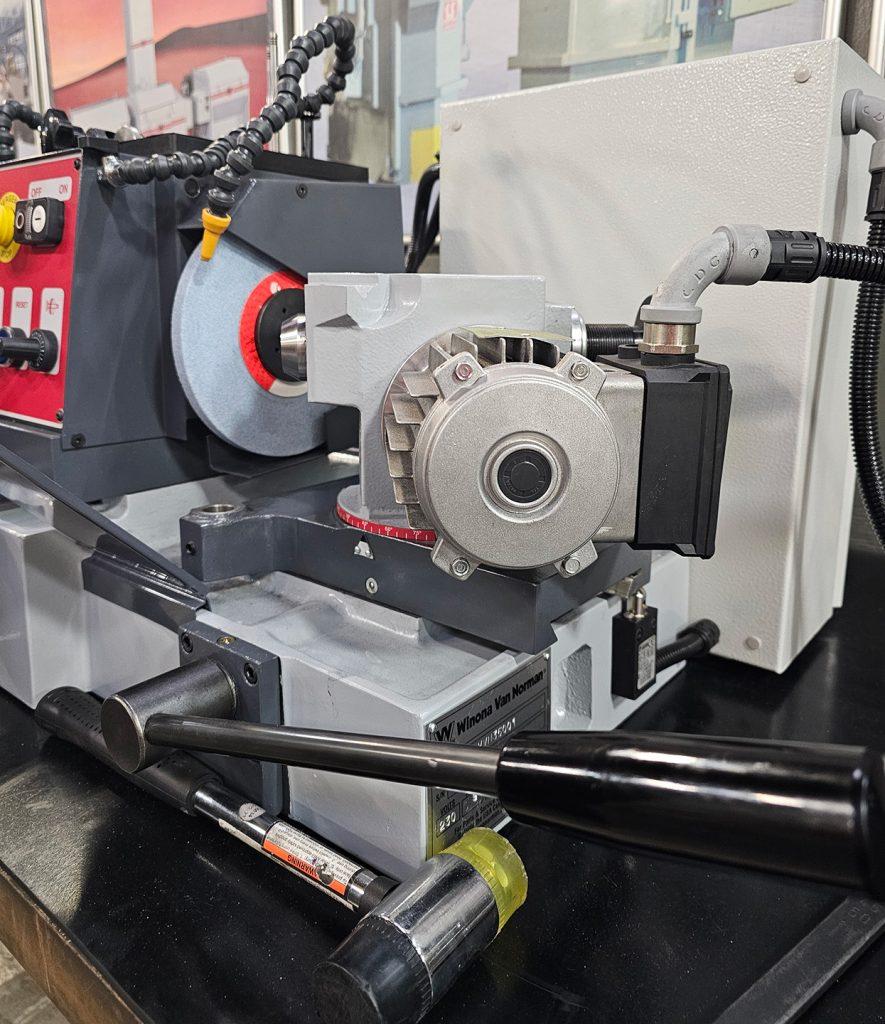

Valve Refacing Grinder VRX

The VRX Valve Refacing/Grinder machine will reface the valve and also chamfer/recondition the valve stem butt. No belts to replace. Grinding wheels are driven with a direct drive motor for grinding power with no slippage.

The machine is easy to operate, the rigid base is cast for precise performance. The carriages slide on dovetail guides, which make it possible to adjust the clearance. The grinding wheel is fed by the hand crank, the chuck is fed by the handle with adjustable stroke. The valve head stock has an adjustment range from 15° to 60°. The valve is clamped in the head stock by a collet, three collets are standard, which ensure maximum stiffness and accurate centering of the valve and high precision operations. The collet system offers tight concentricity for refacing the valve. Positive stop for valve stem speeds production rate. V‐ways and valve stop for repeatable valve stem butt end grinding and chamfering. Valve to adjust coolant flow. Uses water-based coolant for a superior finish and easy clean up. The standard machine includes coolant attachment with gear pump and settling tank, incorporated in the machine base. Variety of high-quality grinding wheels available for different valve materials. *Two sizes of ball chucks available for high precision, .0002 TIR.

Request A Quote

Product Information

Operations

Specifications

Coolant system, collet from .236‐.354″, collet from .354 ‐ 472″, collet from .472 ‐ .629″, support for diamond holder, grinding wheel 6″ x 5″ (.5″ arbor), valve stop, positive stop, grinding rocker arm fixture, diamond and rest, 1 qt of coolant, service tools, operating manual.