Maximizing Precision and Efficiency: Winona Van Norman’s Crank Grinders

In the world of precision engineering, the tools you choose make all the difference. At Winona Van Norman, we pride ourselves on delivering top-tier crank grinders that cater to a wide array of industrial and automotive needs. Whether you’re managing a small workshop or a large-scale production facility, our machines are designed to meet your specific demands with unmatched reliability and precision.

Our Range of Crank Grinders: A Solution for Every Need

We understand that every operation is unique, which is why our lineup includes crank grinders suited for various production scales and technical requirements. From low production setups to high-output operations, and from traditional manual machines to advanced CNC-controlled systems, Winona Van Norman has the perfect fit for your business.

Versatility in Size and Application

Our crank grinders are built to handle cranks of all sizes. We offer a versatile range of models including:

- 270-1500: Ideal for smaller cranks with a height center of 270 mm and a max distance between centers of 1,500 mm.

- 270-2000: A slightly larger model, also with a 270 mm height center but with a max distance between centers of 2,000 mm.

- 300-2200: For mid-sized cranks, this model offers a 300 mm height center and a max distance of 2,200 mm.

- 360-2600: A robust option for larger applications with a 360 mm height center and a max distance between centers of 2,600 mm.

- 360-3500: The largest in our lineup, featuring a 360 mm height center and a max distance of 3,500 mm between centers.

Machine Highlights: Tailored to Your Operation

Each of our models comes with distinct features designed to maximize performance and ease of use:

- CGA: Embracing the “old school” approach, this model is perfect for skilled operators who prefer traditional machine setups.

- CGX: For those who seek efficiency and precision, the CGX offers advanced CNC controls, making it ideal for modern, high-precision applications.

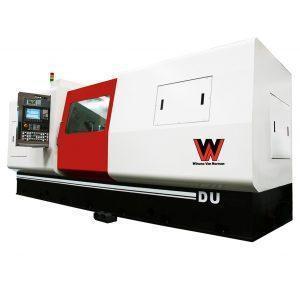

- DU: Time is money, and the DU model is built with speed in mind. This machine can move cranks from floor to floor in minutes, streamlining your production process.

Why Choose Winona Van Norman?

Choosing the right crank grinder is crucial for maintaining efficiency, accuracy, and ultimately, the quality of your products. At Winona Van Norman, we are committed to providing machines that not only meet but exceed your expectations. Our equipment is built to last, delivering consistent results that you can rely on, day in and day out.

Connect with Us

Ready to take your production to the next level? Our team is here to help you find the perfect crank grinder for your needs. Whether you’re upgrading your current equipment or starting from scratch, Winona Van Norman is your partner in precision.

Contact Us Today!

Stay connected and discover more about our offerings:

📞 Phone: +1 316-265-7997

✉️ Email: ekleyhans@winonavannorman.com

📍 Address: 710 E. 17th St. N. Wichita, KS – 67214

#winonavannorman #crankgrinders #manufacturing #cnc #precisionmachining #engineering #industrialequipment #automotiveindustry #machinetools #productionefficiency #crankshaft #mainbearing #crankmachine #crankshaftmachine #grindingwheel #headstock #tailstock #cnccrankgrinder #stroke