SM-E Surface Milling

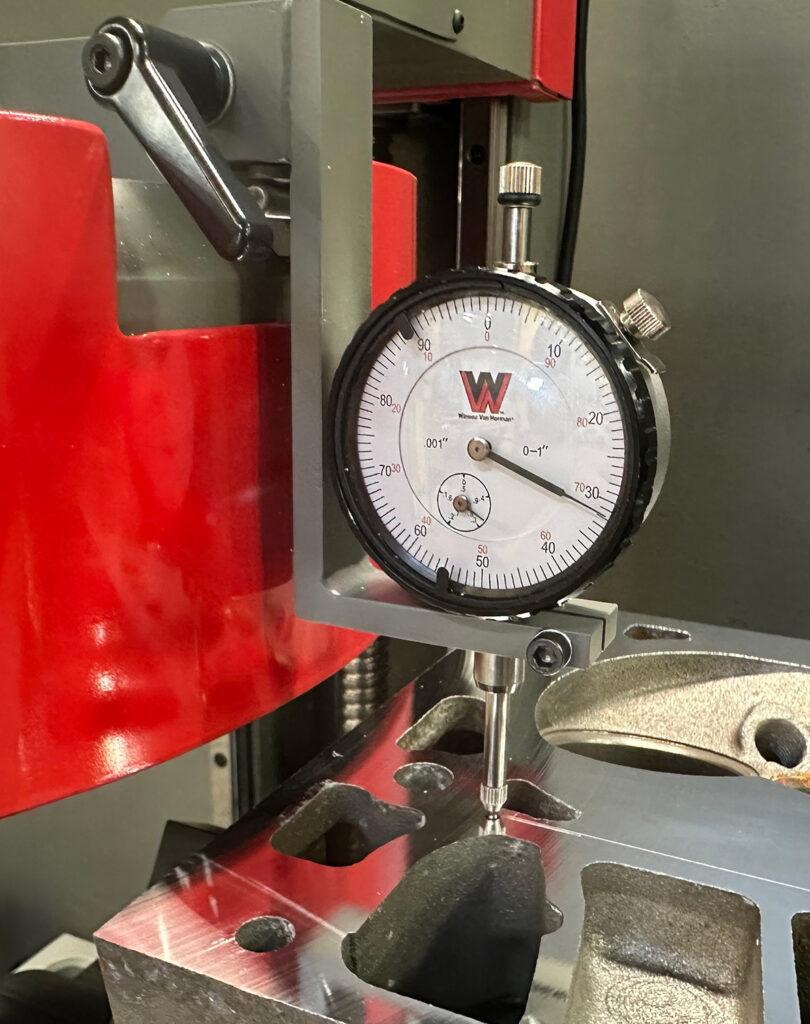

The Winona Van Norman SM-E Surface Milling Machine is engineered for precision, power, and performance in resurfacing small engine cylinder heads, engine blocks, and other critical components. The SM-E combines precise control with operator-friendly design and durable construction to deliver smooth, consistent metal removal and superior surface finishes every time. Its simplified setup and intuitive controls make it easy to achieve repeatable results, reducing setup time and increasing productivity.

Designed to solve common machining challenges, the SM-E restores flatness to warped surfaces for better gasket sealing, ensures consistent finishes that improve engine performance, and minimizes operator fatigue through ergonomic design. With rugged components and easy maintenance access, it offers long-lasting reliability and reduced downtime. Ideal for professional engine rebuilders, the SM-E provides the accuracy, efficiency, and durability required to meet the highest standards of modern engine machining.

Request A Quote

Product Information

Operations

Specifications

Features

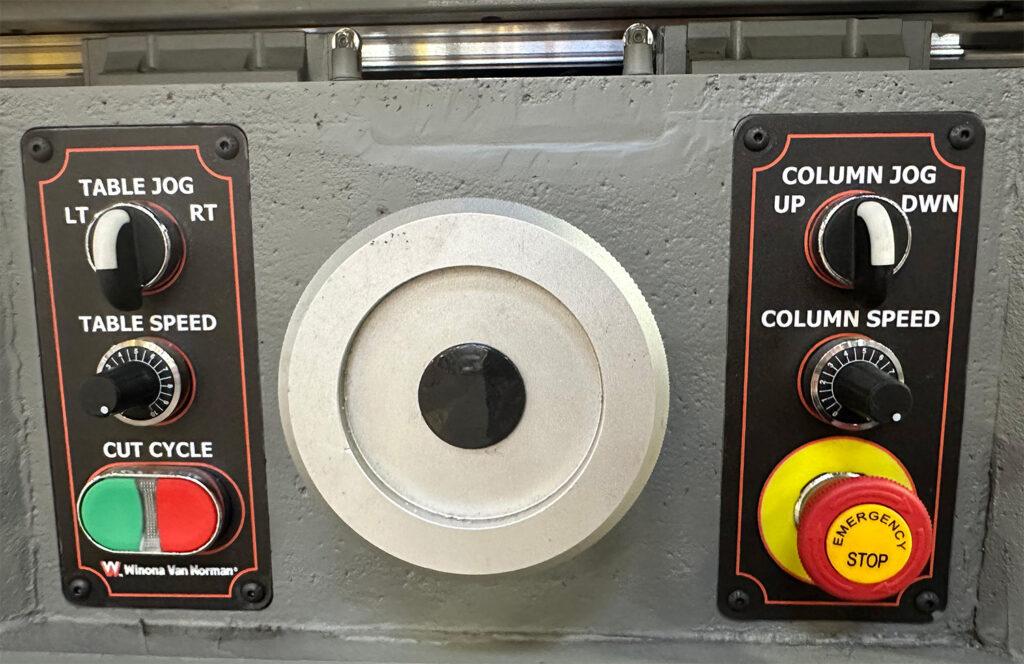

Control Panel

13.75″ Mill Cutter

3 HP Motor

Chip Guard

Ball Screw Drive

Standard Tooling

Manual Control System

CBN Milling Head

Dual CBN Toolholders and Inserts

Wheel Head Puller Bar

Set of Parallels (5.25″ x 16.5″)

Toe Clamp Set (4 Pieces)

Edge Clamp Set (4 Pieces)

Wheel Balancing Arbor

Operation Manual

Features and Options

Motor:

Mill Cutter:

Max. Part Height:

Overall Dimensions:

3 HP

13.75″

15.125″

40″ w x 23.6875″ d x 75″ h